Expanded Perlite

Horticulture

Perlite helps break up compacted soil, allowing for better aeration and drainage of a substrate., making it useful for professional growers and hobbyists alike.

Hydroponic

Expanded perlite is one of the best hydroponic growing mediums around. Used by itself or as a mixture with other mediums.

Construction

Perlite is used widely in the construction market due to its unique characteristics, which are: thermal and sound insulation, low bulk density, fire resistant.

Filtration

Perlite filter aids are lightweight, inert, impart no taste or odour to liquids being filtered and are virtually insoluble in mineral and organic acids at all temperatures.

Insulation

Expanded Perlite (Perlitek) comprises millions of tiny glassy air bubbles particles that act as insulation cavities and reduce heat transmission resulting in significant savings in heating and cooling costs.

Other Applications

Industrial applications for perlite are the most diverse, ranging from high performance fillers for plastics to cement for petroleum, water and geothermal wells.

Horticulture

Perlitek is a lightweight, non-organic, soil substrate that provides a number of important benefits to commercial growers, landscapers, and home gardeners.

Perlitek is ideal for propagation. Various grades of Perlitek are available that can be used solely or with peat moss, sand or other media. An outstanding advantage is that perlite may be used safely without further sterilisation. The light weight properties ensure that when cuttings and seedlings are ready for removal, you can lift them safely and easily from the bed without large clumps clinging to, and damaging the roots. Perlitek also makes sound economic sense, because as it withstands repeated usage, you can replant in the same bed. Some of the benefits of perlite use in horticulture are:

Breaks up Compacted Soil

Root compaction is a serious problem that a lot of substrates can face. Compaction will lead to poor root development and even the death of a plant. Perlite is used to amend substrates like peat moss and soil and does an excellent job of keeping the root zone airy.

Light Weight

Perlite is lighter than grit or sharp sand, pumice, or other aggregates—which can also be used to improve drainage in a garden bed. Adding Perlite to your growing media makes for lighter, easier to handle products for manufacturers, and makes it easier for home

Inorganic

Because it is inorganic, perlite is stable and doesn’t decompose or break down.

Neutral pH

Perlite has a neutral PH 6.5 to 7.5 and is chemically stable.

Aerates Soil

The high displacement and lightweight volume capacity of expanded perlite provide room for air and water, preventing over-watering and allowing proper drainage.

Hydroponic

Perlite was one of the first reliable hydroponic growing mediums available to the horticulture market. You have seen it in the form of hard white bits in potting soil, but perlite can be used by itself in many hydroponic systems.

Propagation of plant cuttings

Perlitek stimulates root growth, and prevents drowning by helping drain excess water away from the cuttings. It can be used with rooting compounds.

Standalone Growing Media

Perlitek is a decent option in some instances as a hydroponic medium. But it is not suitable for high water settings, like deep water culture, or ebb and flow systems.

In mixture with other growing media.

Perlite is commonly mixed with vermiculite in equal amounts (50-50). This greatly solves the water-retaining issue of Perlite while improving the water-holding capacity of vermiculite, making it able to use in the water-rich systems stated above.

Construction

Perlite has been extensively used for years as an aggregate in lightweight, insulating concrete and plaster, and as a loose fill insulation material for concrete masonry blocks, cavity walls, and in residential homes. It is also are used in a variety of specialty applications ranging from fireproofing sprays, chimney fills, interstitial floors, acoustical sprays, etc.

For the purposes of the building industry, since this is where the benefits are most felt, here are some of the top advantages of this unique material.

Here are just a few examples of how the construction industry uses perlite:

- Insulating concrete

- Plaster

- Tape joint

- Ceiling tiles

- Fireproofing sprays

- Acoustical sprays

- Cement stucco

Filtration

Perlite filter aids are lightweight, inert, impart no taste or odour to liquids being filtered and are virtually insoluble in mineral and organic acids at all temperatures. Solubility in strong alkaline solutions varies depending on temperature and contact time. Without using a filter aid the solid particles in the liquid will soon accumulate on filtering surfaces and block them.

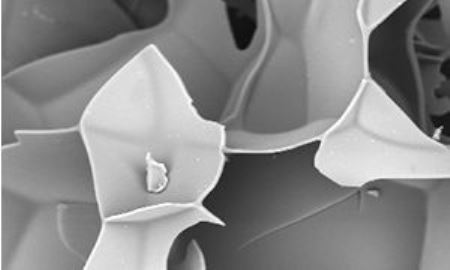

High quality perlite filter aids form a porous layer on the filter element (or septum) and trap the solids, preventing them from blinding. This type of filtration is mechanical—not chemical— and removes solid particles from a liquid filtrate.

The structure of the particles must be such that they will not pack too closely. This not only permits high initial liquid flow but also provides pore spaces to trap and contain the filterable solids and leave a high percentage of channels remaining open for flow.

Advantages of Perlite Filter Aids

- Non-toxic / non-carcinogenic – Chemically inert

- Environmentally friendly and safe to use

- Economical – offers twice as much filtration pound for pound

- Lightweight – up to 50% density advantage

- No color, taste or odor

Clarity is considered by many engineers to be the most important measure of efficiency in filter aid filtration. Selection of the particular type and grade of filter aid having the correct particle size and distribution is a major factor. After these, it’s necessary to consider the quantity of filter aid to be used, the flowrate needed to meet plant production schedules, equipment limitations, and general filtration conditions.

Insulation

Expanded Perlite (Perlitek) comprises millions of tiny glassy air bubbles particles that act as insulation cavities and reduce heat transmission resulting in significant savings in heating and cooling costs.

Masonry Fill Perlite

Expanded perlite provides a quick, inexpensive and permanent method for insulating masonry walls. Depending upon design conditions, reductions in heat transmission of 50 percent or more can be obtained when perlite loose fill is used in the hollow cores of concrete block or cavity type masonry walls.

Cryogenic/Hight Temperature Insulation

Expanded Perlite (Perlitek) is an inorganic product that does not support combustion, or rot, nor does it provide a habitat for rodents. It is ideal for low and high-temperature applications such as

- LNG, LAR, LIN, LOX and Ethylene Tanks

- Cryogenic and Low Temperature Storage Tanks

- Cryogenic Perlite for Insulation for Evacuated Services

- Cryogenic Perlite for Non-Evacuated Services

- Air Separation Units (Cold Box Insulation)

- Cold-Boxes, Heat-Exchangers and Cryo-Drains

- Shipping Containers

- Test Chambers

- Food Processing

Other Applications

Industrial applications for perlite are the most diverse, ranging from high performance fillers for plastics to cement for petroleum, water and geothermal wells. In foundry applications, at molten metal temperatures the perlite granules expand and form a low density, high volume crust which mops up the slag, which can be lifted off the metal with ease leaving behind a clean surface.

Perlite is used in environmental applications to absorb oil, and to control and clean up pollution. It is also blended with soil to filter stormwater runoff, reduce rainwater surge from green roofs, and solify industrial sludge.

WE WOULD LOVE TO HEAR FROM YOU

Click to get in touch with our friendly and experienced team.